Input battery

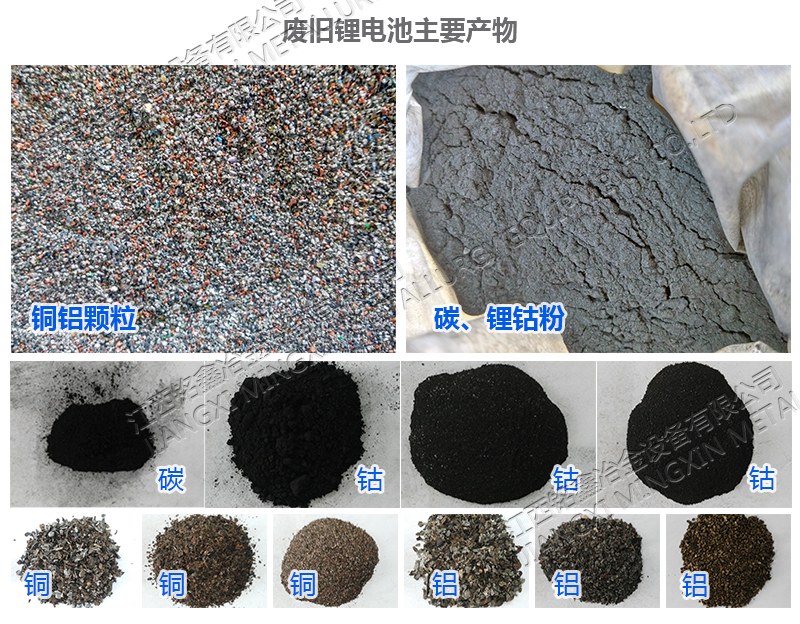

Final output

Customer-Proven Solutions: Lifetime Tech Support and 50+ Success Cases

Why did they decide to choose MINGXIN lithium battery recycling equipment?

what are their real advantages

1.Versatility in all types of lithium-ion batteries

The line is suitable to process all the types of lithium-ion batteries (not only limited to EV battery cell, NMC or LFP,electric scooters', laptops', computer',mobiles', pouches')... all together.

2.Safety Features

Secure and Sealed Direct Shredding: Direct shredding without discharge, minimizing risk.

Temperature and Oxygen Monitoring: Internally closed system with real-time temperature and oxygen checks.

Nitrogen Purge Equipment: Additional safety through tighter sealing and nitrogen purging.MX1000 Liquid Nitrogen Tunnel Freezing Device

4. Advanced Electrolyte Processing

Promote the innovative approach to processing electrolytes:

Adjustable Drying System: Dryer with adjustable temperature (150-400°C) for effective electrolyte removal based on material humidity.

Heat Utilization: Rotary kiln system uses heat from cracked gas for energy recovery.

Secondary Combustion Chamber: Excess gas combustion for maintaining high processing efficiency.

The calorific value of the electrolyte is significant, with properties such as a boiling point of 248°C and a flash point of 160°C. Our rotary kiln system efficiently utilizes the heat from cracked gas for energy recovery, with excess gas directed to a secondary combustion chamber for further combustion, maintaining high processing efficiency.

5.Simplified and Efficient Operation

Shortened Process Flow: Reduced complexity and length of the recycling process.

Lower Energy Consumption: Design focused on energy efficiency.

High Metal Recovery Rate: Improved purity and volume of recovered metals.

Normally a lithium battery is mainly consisted of five parts

1. Cathode --- Copper foil with graphite coating. Binder is SBR

2. Anode --- Aluminum foil with Nickel,Li,Cobalt etc. Oxide. Binder is PVDF

We call Graphite,Li,Nickel,Cobalt oxide mixture “Black Powder”

3. Foil Separator -- PP material to separate cathode and anode

4. Electrolyte -- Lithium salts and organic solvents

5. Housing -- Steel,aluminum or polymer.

2MT/HR Lithium Battery Recycling-Efficient and reliable lithium battery recycling machine offering capacities from 500 to 2000 kg/h-Recycle machine manufacturing inc |Jiangxi Mingxin since 1988

2MT/HR Lithium Battery Recycling-Efficient and reliable lithium battery recycling machine offering capacities from 500 to 2000 kg/h-Recycle machine manufacturing inc |Jiangxi Mingxin since 1988