Case Profile: South Korean Trial Project

Project Overview: The lead acid battery recycling plant in South Korea showcases cutting-edge technology designed to efficiently recycle waste car batteries. This project focuses on utilizing the MX-1025 model, renowned for its reliability and consistent performance in battery recycling operations.

Installation Date: May 2024

Running Date: [To be updated upon commencement]

Technical Specifications:

- Model: MX-1025

- Dimensions: 2376 x 9760 x 4000 (mm)

- Capacity: 4000 kg/h

- Voltage: 380V 50Hz (Customizable)

- Lead Recovery Ratio: >98%

- Plastic Recovery Ratio: >98%

- Acid Recovery Ratio: >96%

Suggested Site Requirements:

- Workshop Height: >7000 mm

- Door Width: >4000 mm

- Door Height: >5000 mm

- Load Bearing: >15 MT

Video showed

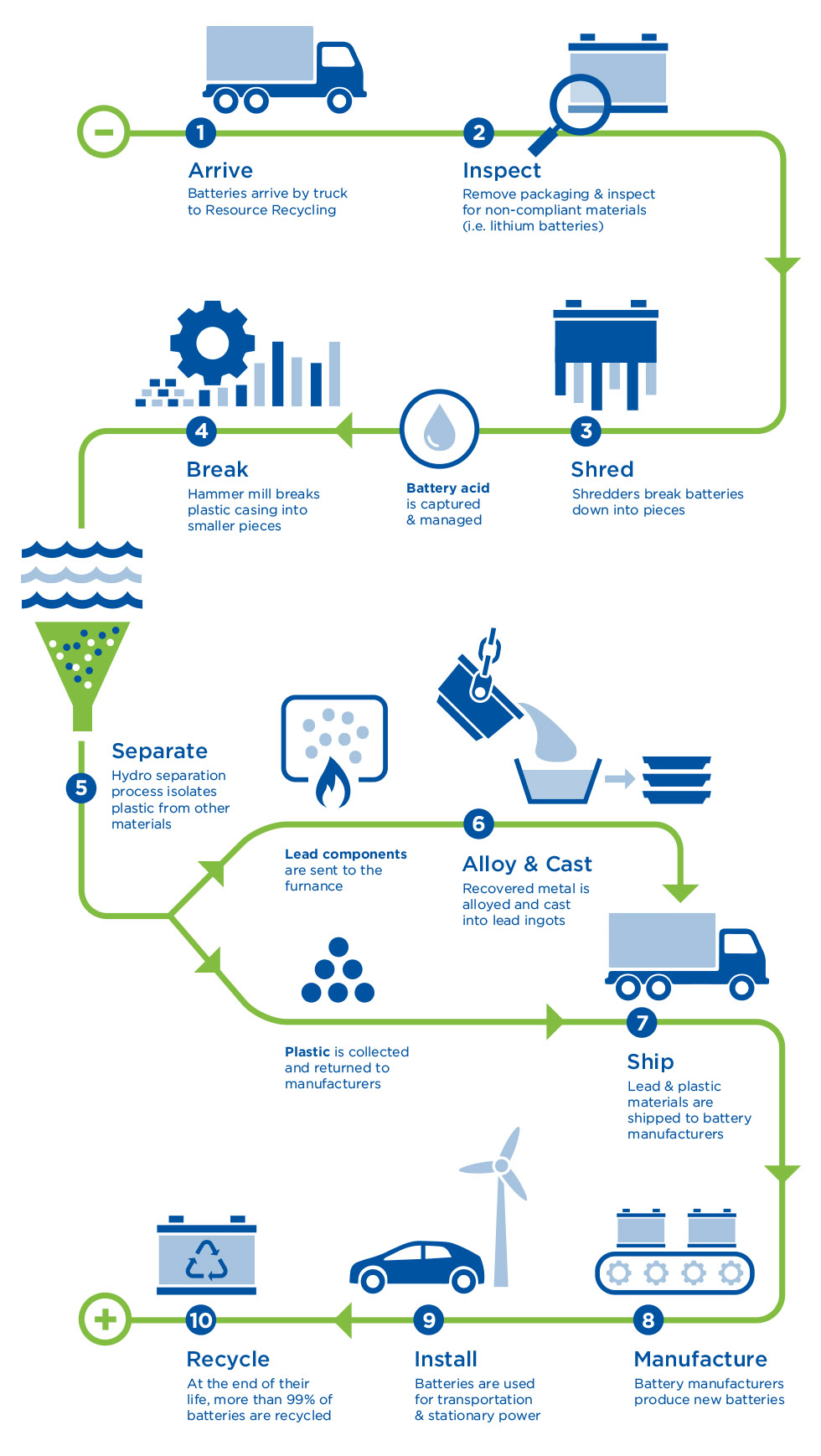

Work Flow: The plant employs a sophisticated mechanical process to systematically separate components of waste car batteries:

- Battery Crushing: Initial crushing of batteries into smaller fragments.

- Separation: Segregation of acid, lead paste, plastic, and lead grids.

- Lead Recovery: High-efficiency recovery of lead granules and paste (>98%).

- Plastic Recovery: Separation and recovery of plastic components (>98%).

- Acid Recovery: Efficient recovery of residual acid (>96%).

Output Products:

- Purity of Refined Lead: 99.97%

- Clean Plastic Granulates

- Concentrated Acid

Customer Benefits: The South Korean plant integrates advanced technology to minimize environmental impact and maximize resource recovery. High recovery rates for lead, plastic, and acid ensure operational efficiency and economic viability. Automated processes reduce manpower and operational costs, enhancing overall sustainability.

Customer Site and Visits: Prospective clients are invited to tour operational sites to witness the plant's efficiency firsthand. Operational facilities are available for visits in Russia, Taiwan, Kenya, Zambia, and other locations, providing insight into the effectiveness of our battery recycling solutions.

Additional Information:

- Electricity Requirements: The electricity consumption varies depending on the size of the plant. For instance, a typical plant producing approximately 300 metric tons of lead per month consumes approximately 120 kWh per metric ton.

- Battery Compatibility: Our system accommodates Maintenance Free Batteries and Car Batteries separately in batches. The recovery efficiency for lead metal content fed into the furnace is consistently high, averaging around 99%.

- Furnace Comparison: The recovery percentages mentioned earlier may vary slightly between Blast Furnace and Rotary Type Furnace configurations, reflecting specific operational efficiencies and processes tailored to each furnace type.

Operation of 4MT/H Car Battery Recycling Line in South Korea-case-Recycle machine manufacturing inc |Jiangxi Mingxin since 1988

Operation of 4MT/H Car Battery Recycling Line in South Korea-case-Recycle machine manufacturing inc |Jiangxi Mingxin since 1988